Description

Posi Quiet brake pads are manufactured using the same positive molding process utilized by Original Equipment suppliers. Positive molding uses extreme pressure to compress the friction material and bond it to the backing plate. This process assures consistent friction material density throughout the pad, resulting in even wear and performance characteristics throughout the life of the brake pad. The number one reasons for dissatisfaction with brake pads are noise and vibration. Centric Parts has recognized these issues and is constantly improving its products to eliminate these issues. Posi Quiet brake friction features either precision cut or shaved backing plates and mechanically attached shims; these small details ensure proper fitment in the caliper and virtually eliminate noise associated with pad vibration. In addition to these features Centric Parts has added a scorching process to all of its Posi Quiet brake pads. This additional process forces any impurities out of the friction material and pre-burnishes the pads to greatly accelerate the break-in process.

- Extreme pressure compresses the friction material creating a more consistent material density throughout the pad This process utilized by O.E. suppliers is the most advanced available today

- Precision cut or shaved backing plates reduce vibration and noise by ensuring proper fit in the caliper, correct fitment results in even pad wear and consistent braking power throughout the lifetime of the brake pad

- All Posi Quiet brake pads feature mechanically attached, application specific shims, these shims provide superior noise abatement compared to lesser adhesive or drift-lock style shims

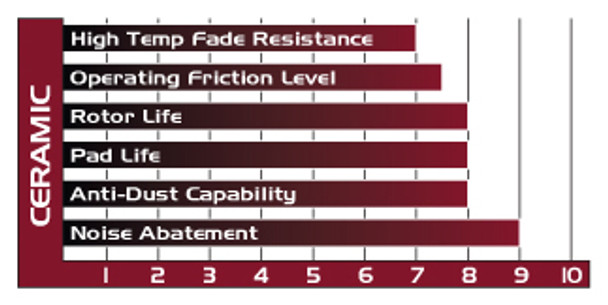

- Stable friction performance across wide temperature range

- Ensures better braking performance with minimal noise